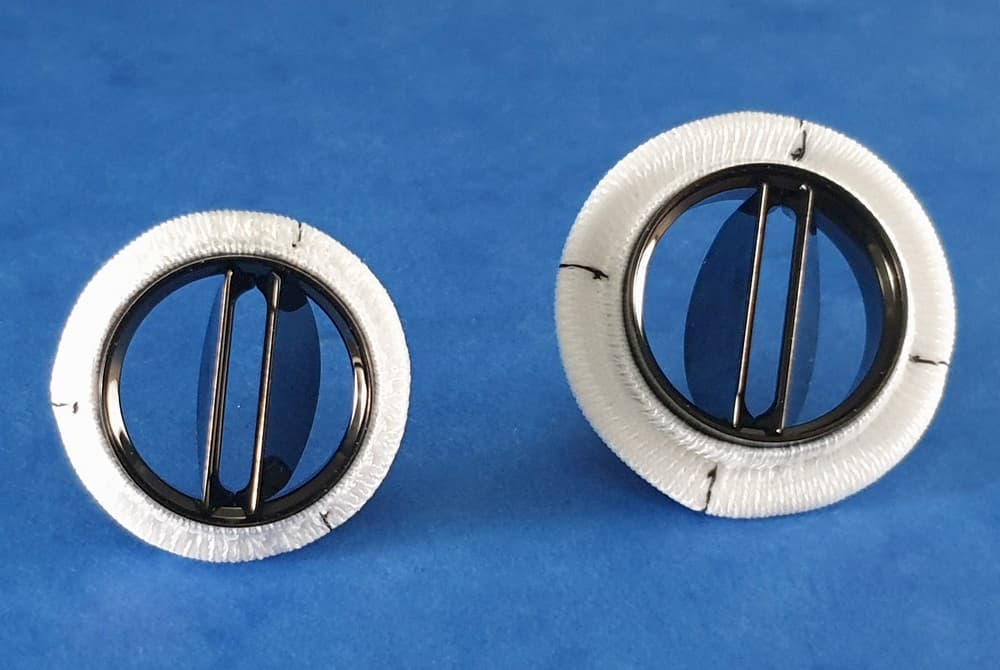

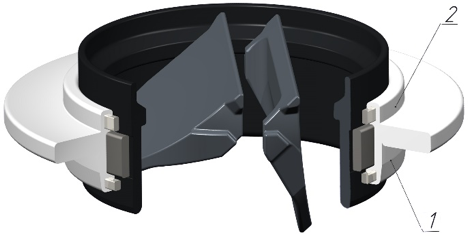

Over the past decade, the CardiaMed valve has shown its performance, with over 120.000 implants worldwide. Its distinguishing design with freely rotating and aerodynamically shaped leaflets made of solid pyrolytic carbon, assures resistance to wear and thrombosis. During surgery the easily rotating leaflets as well as the soft sewing cuff make it easier to implant the CardiaMed valve.

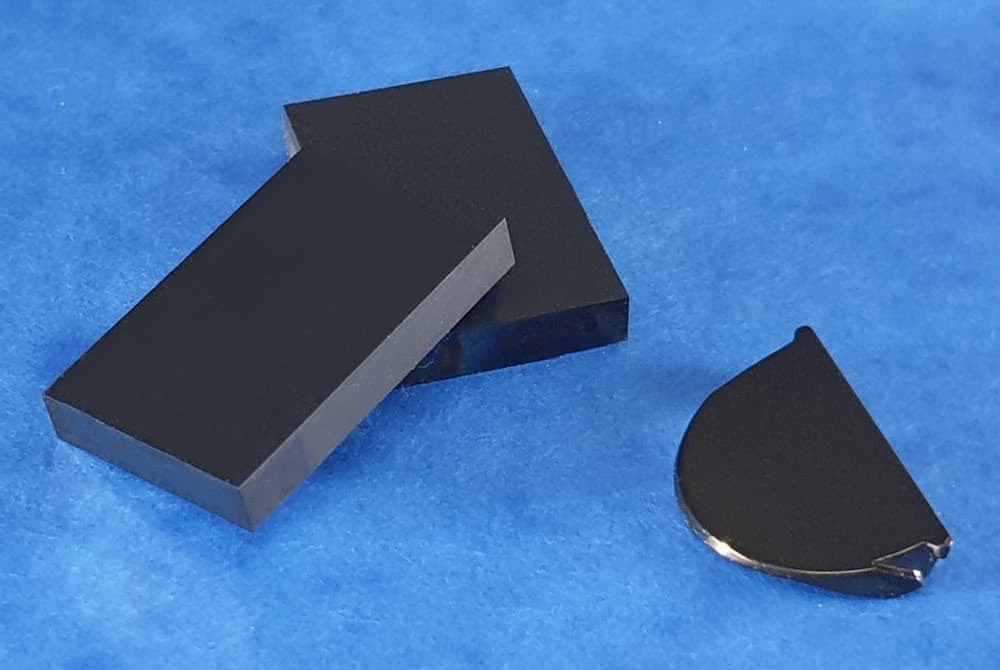

Essential in the design of the CardiaMed valve, was the surgeons’ request to use solid pyrolytic carbon for both the leaflets and the housing of the valve instead of a thin carbon coating. CardiaMed produces the Solid Pyrolytic Carbon in-house. The solidity and isotropy of this nanocomposite allows manufacturing of valve parts with 1 micron precision, without compromising the strength of the material. The solidity of the leaflets and housing prevents variable thickness of the material that occurs with carbon coating. The CardiaMed valve provides unmatched strengths and durability. The unmatched smoothness of the surface lowers the risk of thrombosis.

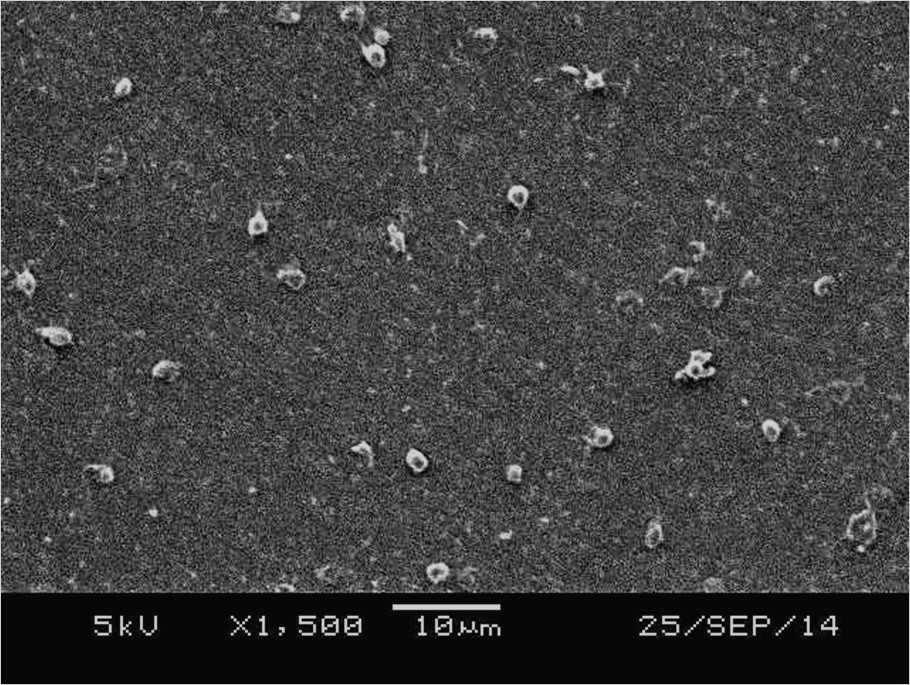

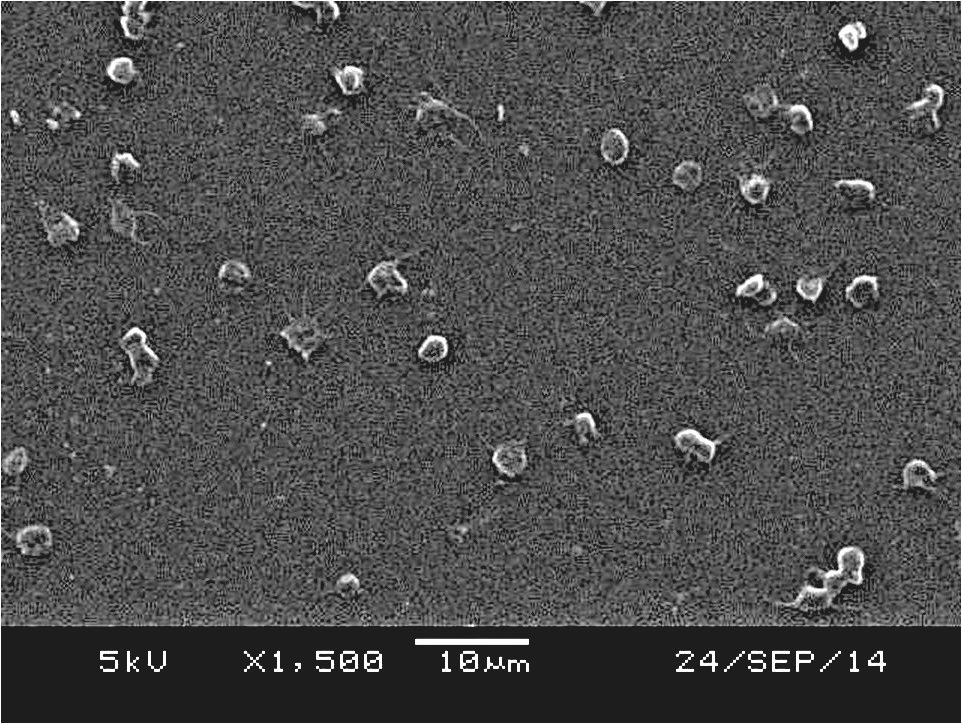

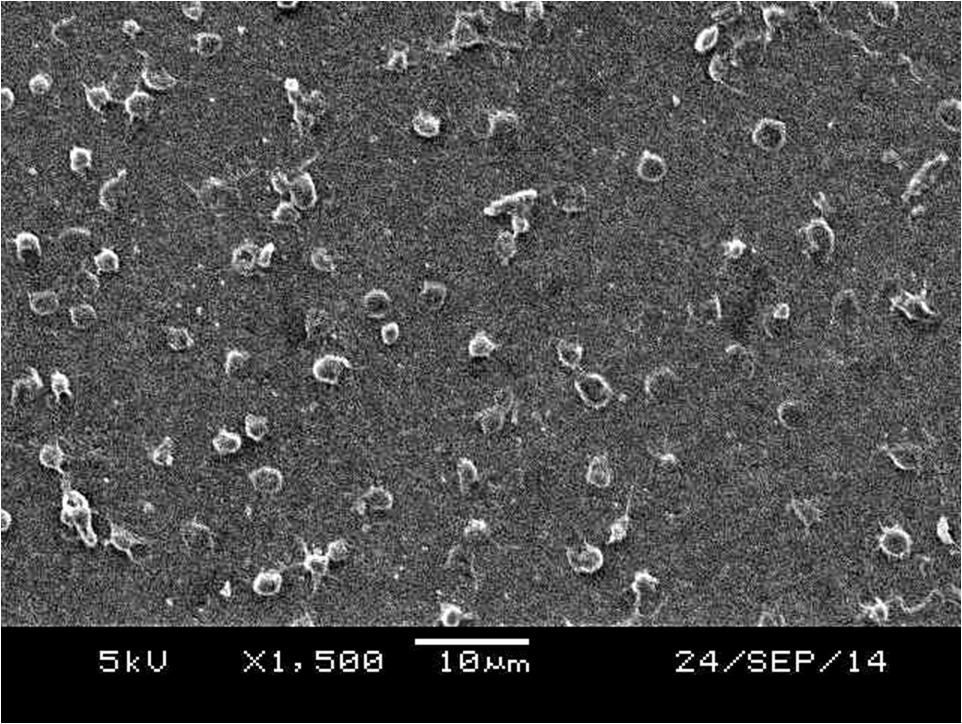

Lower Relative index of Platelet adhesion (RIPA) compared with other prosthetic heart valves.

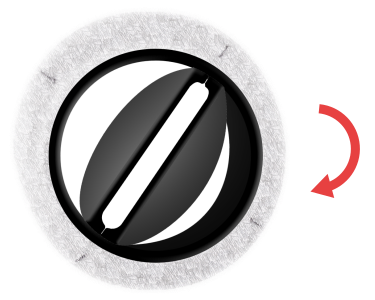

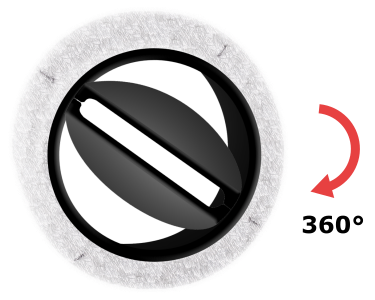

The design of the CardiaMed heart valve eliminates the traditional pivots of bi-leaflet mechanical heart valves. The use of solid pyrolitic carbon enabled more complex 3D shapes.

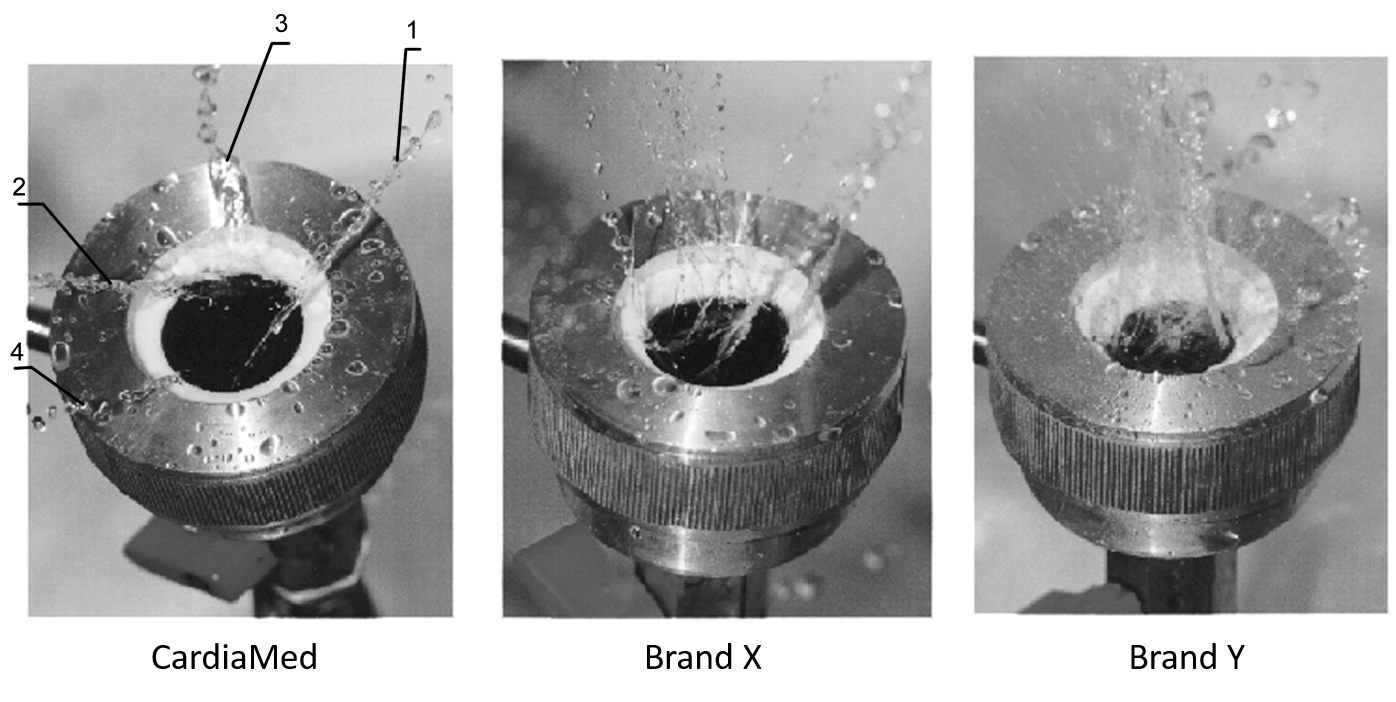

Frequently thromboses of mechanical heart valves are related to the pivoting area. By eliminating the traditional hinges, washing problems have become a thing of the past

The optimised hemodynamic profile of the leaflets:

The back-flow of the CardiaMed valve has been a major part in the design of the valve. The valve generates a controlled regurgitant blood flow that consists of 4 powerful, intended and controlled jet streams.

Always an optimal choice of sewing cuff. Read more about the sizes: sizes aortic heart valves and sizes mitral heartvalves.